Ink rollers, also known as rubber rollers, are essential tools for many industries, including printing, textiles, industrial manufacturing, food processing, and medical and pharmaceutical industries. Ink rollers play a crucial role in the application of ink to various materials, making them an integral part of the manufacturing process. In this article, we will discuss the creation and variations of ink rollers, as well as the environmental and health and safety considerations that come with their use. We end this article by discussing the benefits and various applications of ink rollers Read More…

Harwood Rubber Products provides top quality rubber rollers and a variety of custom products. We are capable of producing a great diversity of rolls and coverings for a broad customer base.

Since 1948, REDCO Rubber Engineering & Development has been manufacturing rubber rollers, idler rolls and conveyor rollers. We serve industries such as computers, printers and paper handling.

Our guide rollers are made from the highest quality materials in the industry. We take pride in adhering to our company values, like integrity and honesty. As a family owned and operated company, we like to treat customers like our own family. We will always look for the best prices and the prefect solution. Give us a call today to see how we can help you meet your goals!

TPC, Inc. is a dedicated and trusted manufacturer of rollers. We manufacture rollers in all shapes, sizes, designs, and colors to meet the needs of our customers and keep their process moving. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

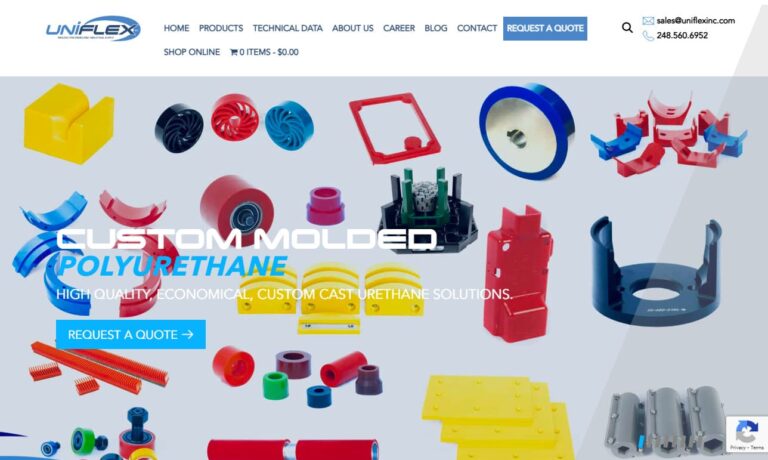

Since 1979, Uniflex has been a leading manufacturer of urethane products. We provide high-quality urethane rollers and urethane castings, as well as urethane molded products available in an array of colors. Uniflex offers customized body blocks and engine components for the automotive industry. Our team is dedicated to advancing our company and raising industry standards.

More Ink Roller Manufacturers

The Creation of Ink Rollers

Ink rollers, also known as printing rollers or inking rollers, are essential components in a wide range of industrial and commercial printing and marking applications. The manufacturing process of ink rollers can utilize several methods, each offering unique advantages depending on the intended use, required durability, and specific material properties.

Key production methods include injection molding, compression molding, transfer molding, and extrusion. The chosen ink roller manufacturing technique is influenced by factors such as the type of rubber or elastomer, required roller hardness, and application-specific performance demands.

- Injection molding for ink rollers: This popular method involves melting synthetic or natural rubber and injecting it into a precisely engineered mold. The mold is cooled, forming ink rollers with consistent dimensions and surface qualities. Injection molding is ideal for producing high volumes of uniform rollers used in offset printing and high-speed flexographic presses.

- Compression molding: In this process, pre-measured rubber is placed into a heated mold cavity and compressed under high pressure. The heat and pressure form the roller to exact specifications. Compression molding is suitable for custom ink rollers, large diameters, or when specialty compounds are needed for chemical resistance or abrasion resistance.

- Transfer molding: This hybrid technique heats rubber in one chamber, then uses a plunger to transfer it into a mold. Transfer molding offers tight tolerances and is used for ink rollers that require complex geometries or embedded metal cores for advanced printing machinery.

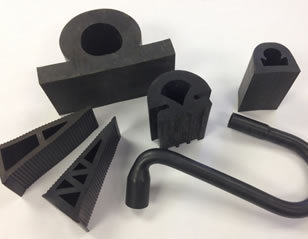

- Extrusion for ink roller production: Extrusion forces rubber through a die, creating continuous sheets or cylindrical shapes. These are then cut and further processed into rollers. This method is excellent for long, continuous rollers or when custom lengths and profiles are required for specialized industrial printing applications.

Curious about which ink roller manufacturing process is best for your industry? Consider the specific performance requirements, production scale, and desired material properties when selecting a fabrication method for your ink rollers. Consulting with an experienced ink roller manufacturer can help you determine the most cost-effective and reliable process for your business needs.

Variations in Ink Rollers

Ink rollers are highly customizable, with variations in design, construction, and material composition to suit diverse industrial applications. Selecting the right ink roller type is crucial for optimizing print quality, reducing maintenance costs, and ensuring compatibility with inks and substrates.

- Surface design: Ink rollers may feature smooth, grooved, or textured surfaces. Smooth rollers are ideal for uniform ink transfer, while textured or patterned rollers can provide specialized effects or enhanced grip for challenging substrates.

- Edge profile: Rollers can have straight or tapered edges. Tapered rollers are often used in applications where precise control of ink flow is needed, such as in fine-line or multi-color printing presses.

- Construction: Ink rollers can be solid throughout or feature a hollow core. Hollow rollers reduce weight and can improve rotational speed in high-throughput printing lines, while solid rollers offer superior durability and resistance to deformation.

- Material composition: Common materials include natural rubber, EPDM, nitrile, silicone, polyurethane, and specialty elastomers. Each material offers distinct benefits in terms of chemical resistance, durability, elasticity, temperature tolerance, and ink compatibility.

For example, silicone ink rollers are widely used in food processing, medical device labeling, and cleanroom printing due to their non-reactive, odorless, and food-safe properties. Natural rubber ink rollers, on the other hand, are preferred in traditional printing presses for their excellent ink transfer, flexibility, and cost-effectiveness.

Wondering which ink roller material is best for your printing or manufacturing process? Assess the types of inks used (solvent-based, water-based, UV-curable), the substrates being printed (paper, plastic, metal, textiles), and environmental conditions (temperature, humidity) to identify the optimal ink roller material for your application.

Considerations Regarding Ink Rollers

When evaluating ink rollers for your production line, there are several critical considerations beyond the basic performance characteristics. These include environmental impact, worker safety, roller maintenance, and overall lifecycle cost.

- Environmental impact: The production of ink rollers can involve the use of chemicals, energy-intensive processes, and non-renewable raw materials. Sustainable manufacturing practices and recycling initiatives are increasingly important in the ink roller industry to minimize environmental footprints.

- End-of-life disposal: Improper disposal of used ink rollers can contribute to landfill waste and environmental pollution due to lingering inks and non-biodegradable components. Consider suppliers offering take-back or recycling programs to ensure responsible roller disposal.

- Worker safety: Manufacturing and handling ink rollers may expose workers to potentially hazardous chemicals, fumes, or skin contact with uncured rubber compounds. Proper ventilation, personal protective equipment (PPE), and safe handling protocols are essential for workplace safety.

- Health considerations: During routine use, there is a risk of ink transfer to the skin or eyes, which can lead to irritation or sensitization. Choose rollers designed for easy cleaning, and ensure operators are trained in safe ink handling and spill response procedures.

- Maintenance and replacement: Ink rollers are subject to wear and degradation over time. Regular cleaning, inspection, and timely replacement are vital for maintaining print quality, reducing downtime, and prolonging equipment lifespan.

Have questions about ink roller safety, compliance, or environmental impact? Reach out to leading ink roller suppliers to learn about their certifications, sustainable practices, and safety data sheets for each roller product.

The Benefits of Ink Rollers

Investing in high-quality ink rollers delivers a range of benefits that can positively impact your production efficiency, product quality, and bottom line. Whether used in commercial printing, industrial marking, or product packaging, the right ink roller solution is essential for operational success.

- Consistent and precise ink application: Engineered for uniform ink distribution, premium ink rollers ensure even coverage and minimize printing defects such as streaking, banding, or smudging.

- Increased efficiency and productivity: Durable, high-performance rollers reduce print downtime, require fewer adjustments, and support faster line speeds—improving throughput and lowering operational costs.

- Versatility across industries: Ink rollers are adaptable to diverse sectors including commercial printing, textile production, packaging, electronics manufacturing, and food processing.

- Customization for unique needs: Modern roller manufacturers offer tailored solutions with custom sizes, core materials, durometers, and surface finishes to meet the exact requirements of specialized printing or coating tasks.

- Enhanced product quality and brand reputation: Accurate ink transfer and high print fidelity support strong branding, regulatory compliance, and customer satisfaction.

Looking to boost your print quality or manufacturing throughput with advanced ink roller technology? Explore our directory of ink roller suppliers and request detailed product specifications or sample rollers to compare performance in your specific application.

Applications of Ink Rollers

Ink rollers are indispensable across a variety of markets and manufacturing environments. Their unique ability to deliver controlled, repeatable ink application makes them the go-to solution for many critical processes. Let’s explore the most common and high-value applications in detail.

Printing Industry

In the printing industry, ink rollers are foundational to the operation of presses ranging from traditional sheet-fed offset presses to modern digital and flexographic presses. Their primary role is to transfer ink from the ink reservoir or tray onto a printing plate (or directly onto the substrate in some presses), ensuring an even, consistent layer that produces crisp images and text.

- Common ink roller types for printing include form rollers, distributor rollers, and transfer rollers—each with a specific function in ink metering and control.

- Ink rollers are critical for achieving color consistency, minimizing waste, and supporting high-speed production of magazines, newspapers, packaging, and labels.

- Advancements such as UV-resistant and anti-ghosting rollers support specialty printing requirements and extended roller life.

Wondering how to select the right ink roller for your specific type of press? Compare roller hardness, surface finish, and compatibility with your preferred ink formulations to identify the best-performing roller for your shop.

Textile Printing and Fabric Decoration

Within textile manufacturing, ink rollers play a pivotal role in processes such as screen printing, rotary printing, and direct-to-garment (DTG) printing. These rollers deliver precise amounts of dye or pigment to fabrics, supporting the production of vibrant, long-lasting prints on a wide range of materials including cotton, polyester, linen, and blends.

- Specially engineered textile ink rollers resist swelling and degradation from aggressive dyes and solvents.

- Consistent ink laydown is essential for achieving uniform coloration and repeatable patterns, especially in mass production environments.

- Rollers can be customized for specific fabric textures, thicknesses, and print effects—such as embossing or metallic finishes.

Need help optimizing your textile printing process? Consult with a textile ink roller specialist to evaluate roller materials and geometries tailored for your ink chemistry and garment types.

Industrial Manufacturing and Product Marking

In industrial manufacturing, ink rollers are key components for marking, labeling, and coding products and packaging. Applications include direct part marking on pipes, cables, metal sheets, and plastic components, as well as applying lot codes, expiration dates, and regulatory information to consumer goods.

- Ink rollers are compatible with a wide range of marking technologies, such as continuous inkjet, pad printing, hot stamping, and contact coders.

- Rollers used in industrial settings are often formulated for resistance to solvents, oils, and high temperatures.

- Clear, durable markings are vital for traceability, quality assurance, and compliance with industry standards (e.g., automotive, aerospace, electronics).

Curious about the best ink roller for your marking or coding application? Review available roller materials and coatings to ensure optimal adhesion, durability, and legibility on your chosen substrates.

Food Processing and Packaging

In food processing and packaging, ink rollers are used to apply expiration dates, batch codes, and branding directly onto food products or their packaging. These rollers must adhere to stringent health and safety standards—often requiring food-grade, non-toxic, and FDA-compliant materials.

- Silicone and polyurethane ink rollers are popular choices for food labeling due to their chemical stability, odorlessness, and ease of cleaning.

- Precision application ensures legible, smudge-proof labels that withstand handling, refrigeration, and moisture.

- Compliance with food safety regulations (such as FDA, EC, or local certification) is a critical purchasing factor for food manufacturers.

Searching for reliable food-safe ink rollers? Request documentation of food safety certifications and inquire about roller cleaning methods to maintain compliance in your facility.

Medical and Pharmaceutical Applications

Within medical device manufacturing and pharmaceutical packaging, ink rollers are essential for accurate product identification, traceability, and regulatory compliance. Applications include labeling syringes, ampoules, vials, medical instruments, and medication packaging.

- Medical-grade ink rollers are designed for sterility, chemical resistance, and compatibility with sterilization processes (e.g., autoclaving, gamma irradiation).

- Rollers must produce legible, durable markings that remain intact throughout product handling and storage.

- Strict adherence to industry standards (such as ISO 13485, FDA, or GMP) is required to ensure patient safety and legal compliance.

Need guidance on medical-grade ink rollers? Contact suppliers with experience in healthcare and pharma applications who can provide regulatory documentation and performance data.

How to Choose the Right Ink Roller Supplier

Selecting the ideal ink roller supplier is a crucial step in ensuring uninterrupted production quality, operational efficiency, and cost control. With so many options in the market, it’s important to evaluate suppliers based on their expertise, product range, customization capabilities, and customer support.

- Industry experience: Look for suppliers with a proven track record in your industry, whether it’s commercial printing, packaging, textiles, or industrial marking.

- Material and product range: Comprehensive suppliers offer a wide selection of roller materials (silicone, natural rubber, polyurethane, etc.), sizes, and custom engineering services to match your unique requirements.

- Certifications and quality assurance: Reputable suppliers provide documentation for ISO, FDA, or other relevant certifications, as well as traceability and batch testing for consistent roller quality.

- Technical support and service: Reliable suppliers offer after-sales support, installation guidance, and troubleshooting to maximize the lifespan and performance of your ink rollers.

- Customization and prototyping: If your process requires non-standard or specialized rollers, prioritize suppliers with in-house engineering and rapid prototyping capabilities.

- Lead times and logistics: Consider the supplier’s production capacity, stock availability, and shipping options to avoid downtime and keep your supply chain efficient.

To ensure you have the most productive outcome when purchasing ink rollers from an ink roller supplier, it is important to compare several companies using our comprehensive directory of ink roller suppliers. Each ink roller supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each ink roller business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple ink roller companies with the same form and efficiently compare pricing, lead times, and product features.

Ready to find the best ink roller supplier for your needs? Browse our supplier directory, compare business profiles, and connect directly with leading manufacturers for quotes, material samples, and expert consultation.

Frequently Asked Questions about Ink Rollers

- What are the most common materials used in ink roller manufacturing? Natural rubber, nitrile, EPDM, silicone, and polyurethane are widely used, each offering unique benefits for print quality, chemical resistance, and durability.

- How often should ink rollers be replaced? Replacement frequency depends on production volume, ink type, roller material, and application environment. Regular inspection for wear, swelling, or surface damage is recommended to maintain optimal print quality.

- Can ink rollers be cleaned and reused? Most ink rollers can be cleaned using compatible solvents or detergents, but care must be taken to avoid damaging the roller surface. Follow manufacturer guidelines for cleaning procedures and recommended cleaning agents.

- What factors affect ink roller performance? Material compatibility with ink and substrate, roller hardness (durometer), surface finish, core construction, and correct installation all influence roller performance and print outcomes.

- Are there eco-friendly ink roller options? Yes, some suppliers offer eco-friendly rollers produced from recycled materials or with reduced environmental impact. Ask suppliers about their sustainability initiatives and green product lines.

Still have questions about ink rollers, materials, or suppliers? Contact our experts or browse our resource center for in-depth guides, case studies, and technical support.

Conclusion: Advancing Your Operations with the Right Ink Roller Solution

Whether you’re running a high-volume print shop, a textile production facility, a food packaging plant, or a medical device assembly line, choosing the right ink roller is fundamental to ensuring consistent results and operational efficiency. By understanding the full range of ink roller types, materials, manufacturing methods, and supplier options, you can make informed purchasing decisions that drive quality, compliance, and profitability.

Ready to take your printing and marking operations to the next level? Browse our ink roller supplier directory today, compare products and capabilities, and request personalized quotes or technical consultations to find the perfect ink roller solution for your business.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

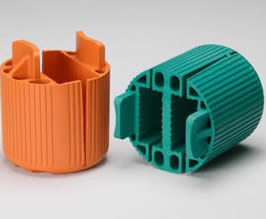

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services